SEMI-RIGID CAR

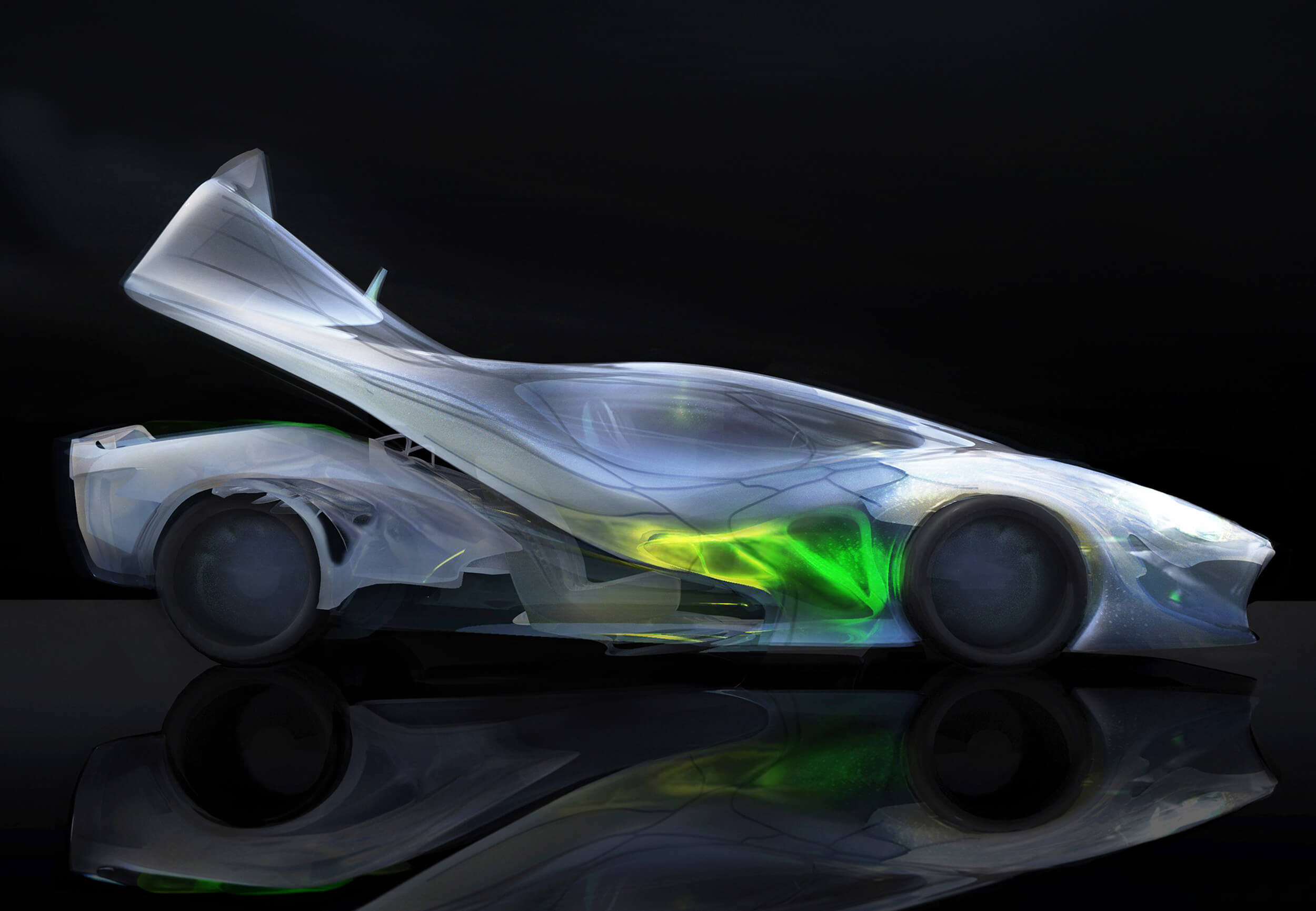

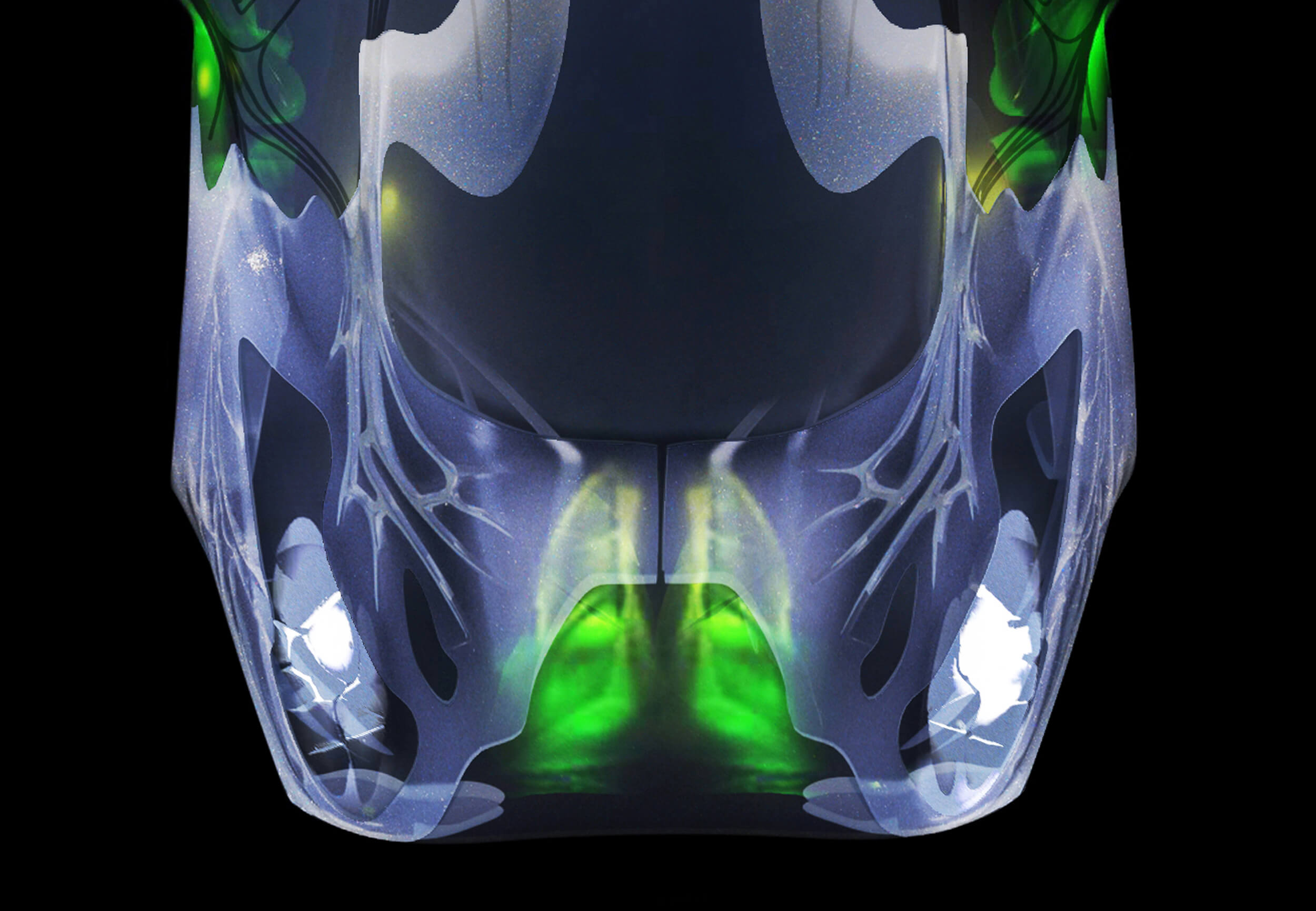

Designed for Renault, the Semi-Rigid Car is an experiment underwritten by the recent revolution in multi-materiality and rapid prototyping. Closer to alchemy than architectural tectonics, multi-materiality allows for unprecedented aesthetic and performative variability—from soft to semi-rigid to stiff or opaque to transparent—using continuous bonding rather than kit-of-parts assembly logic.

Read More

Alchemy over Tectonics

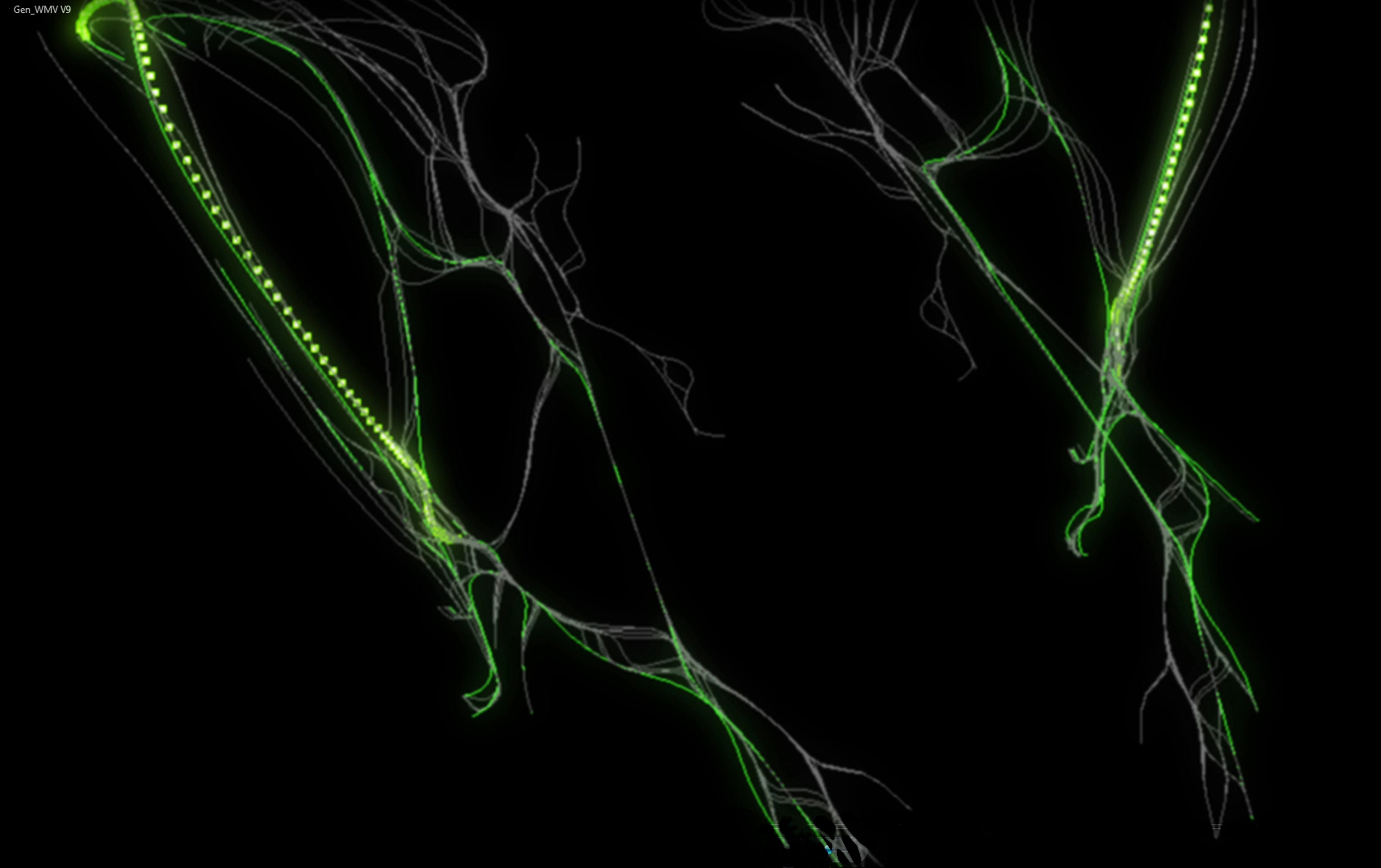

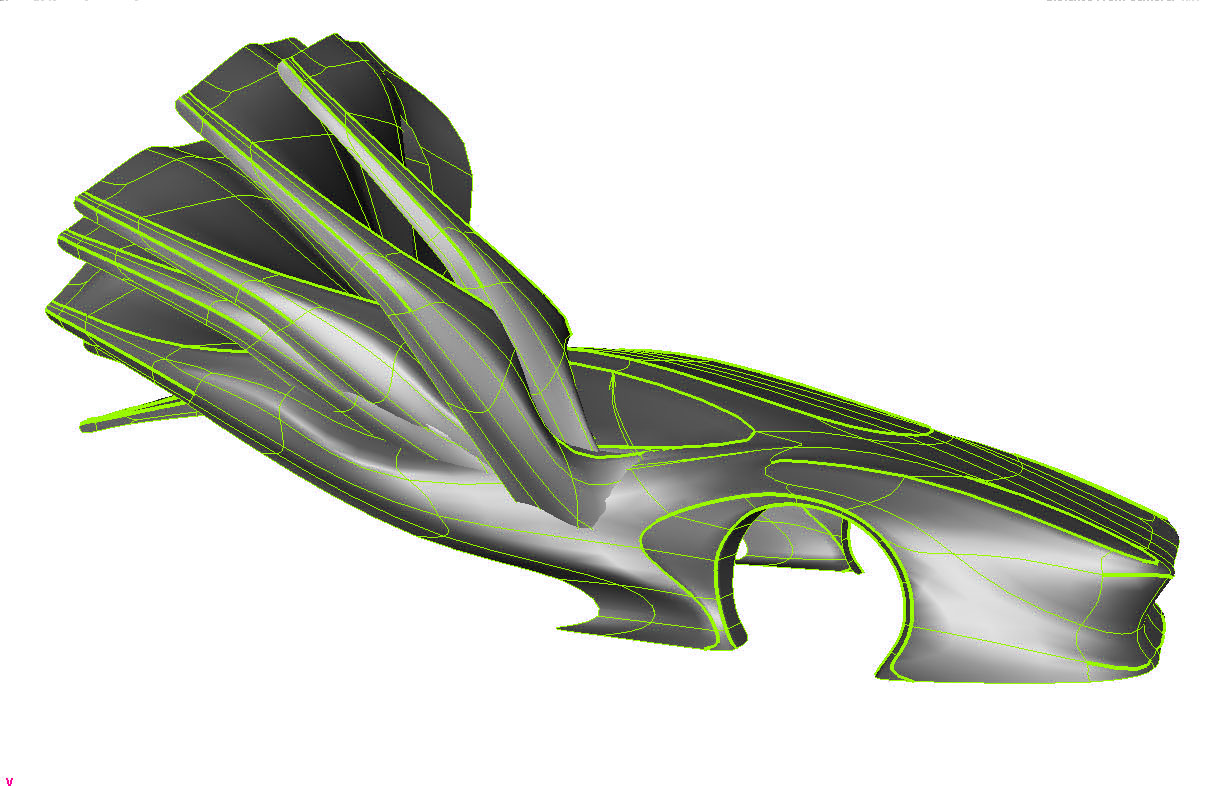

The Semi-Rigid Car takes on the multi-material paradigm at a scale that is almost feasible with today's technology. The mechanical appearance and behavior of steel, glass, sheet metal, and fasteners is replaced with a new language of blending based on compositing synthetic and biological materials in weird molecular arrangements. The combinatorial range of capacities and aesthetic effects of polymers questions the tired frame-and-infill design model based on disparity of material capacities within hierarchical assemblies. Over the last century, automobile chassis design has oscillated between vector frame and unibody models, whereas the paradigm of multi-materiality offers the first real path away from ‘mineral’ materiality.

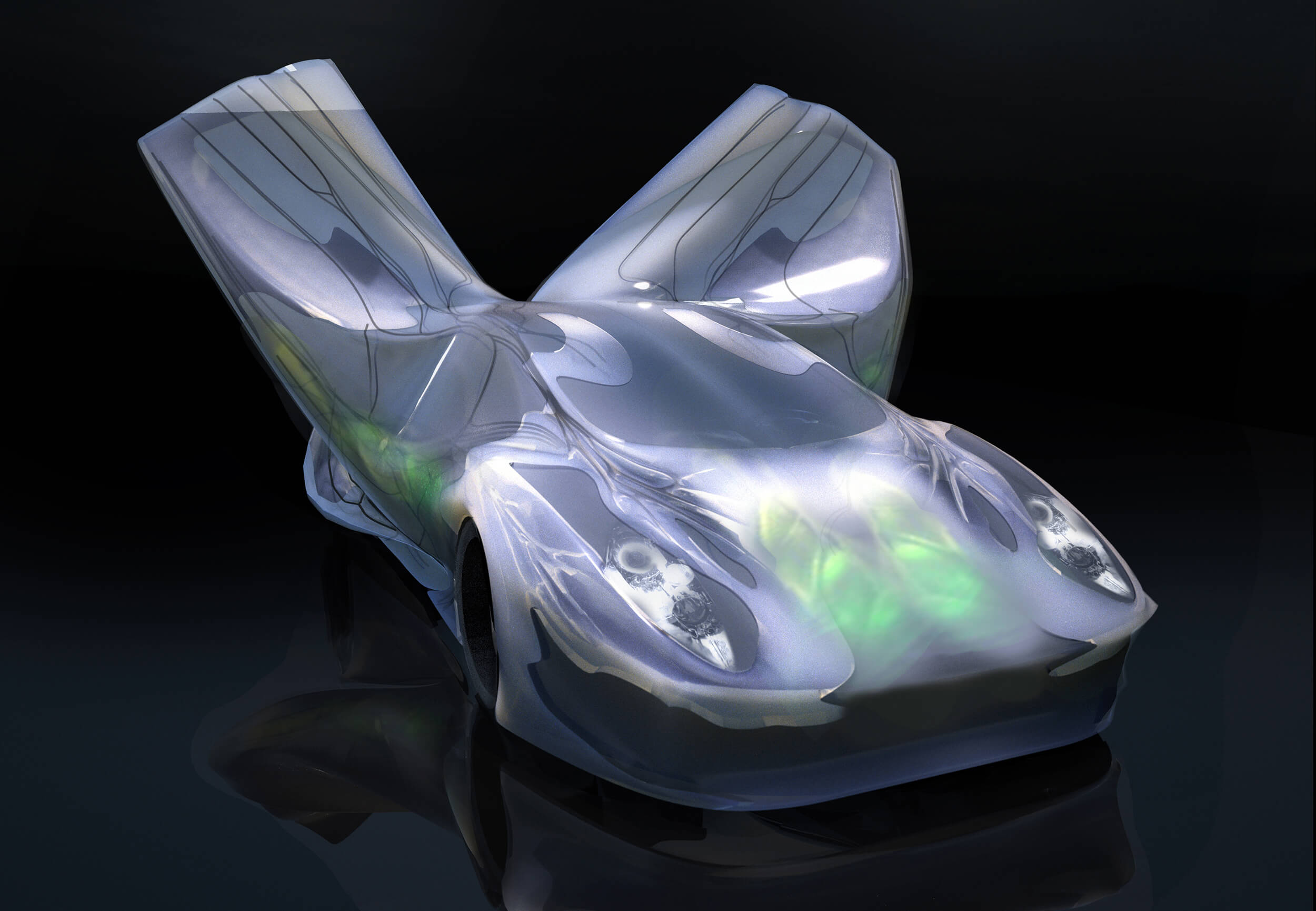

Cartilage and Living Hinges

Similar to the cartilage skeleton of a shark, zones of semi-rigidity can occur as armatures or plate-like formations. The crash safety “crumple-zone” in unibody construction, where front and rear zones self-destruct in order to absorb impact forces, is replaced by the lively springiness of semi-rigid construction. In contrast to the conventional mechanical movements of doors and hoods—involving frames and hinges—openings in the Semi-Rigid Car are based on the living hinge. Doors, opened with tendon-like actuators, quiver, curl, and exhibit other unfamiliar behaviors. Tires and rims are fused and can be 3D printed as one object.

TYPE

Prototype

YEAR

2011

CLIENT

Renault

DESIGN TEAM

PROJECT TEAM

Similar to the cartilage skeleton of a shark, zones of semi-rigidity can occur as armatures or plate-like formations.

Closer to alchemy than architectural tectonics, multi-materiality allows for unprecedented aesthetic and performative variability—from soft to semi-rigid to stiff or opaque to transparent—using continuous bonding rather than kit-of-parts assembly logic.