FIGURAL JOINT

The Qiddiya Performing Arts Centre is the first flagship cultural asset of Qiddiya City in the Kingdom of Saudi Arabia, a city wholly dedicated to play and an epicenter of entertainment, sports, and culture. The project’s mission is to engender fresh interest in the performing arts among Saudi youth by providing pioneering new content for the 21st century, within a building designed as a massive, immersive stage.

Read MoreTWA brings the wonder and mystery of the cosmos down to earth. We believe that architecture’s role in society is not to mirror the status quo, but rather to give glimpses into a better, more beautiful parallel universe. A parallel universe — unlike a truly alien one — draws us in through a combination of familiar and alien things that unsettle our habitual ways of seeing and being on earth.

LOCATION

Tallinn - Estonia

CLIENT

Qiddiya Investment Company, Riyadh

YEAR

2023 - ONGOING

STATUS

Design Development

TYPE

Theatre

DESIGN TEAM

PROJECT TEAM

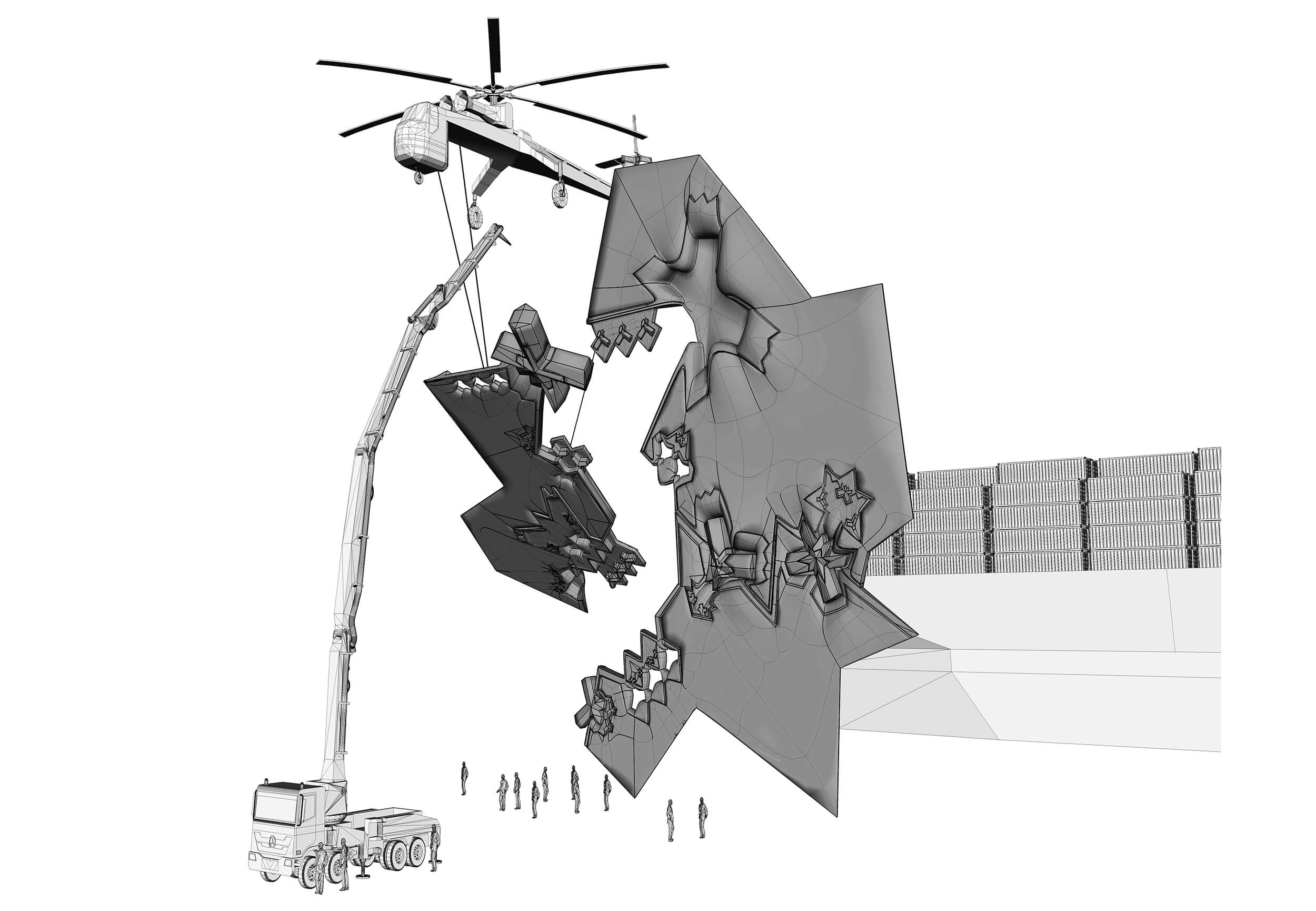

“A stage from another world, built for this world.”

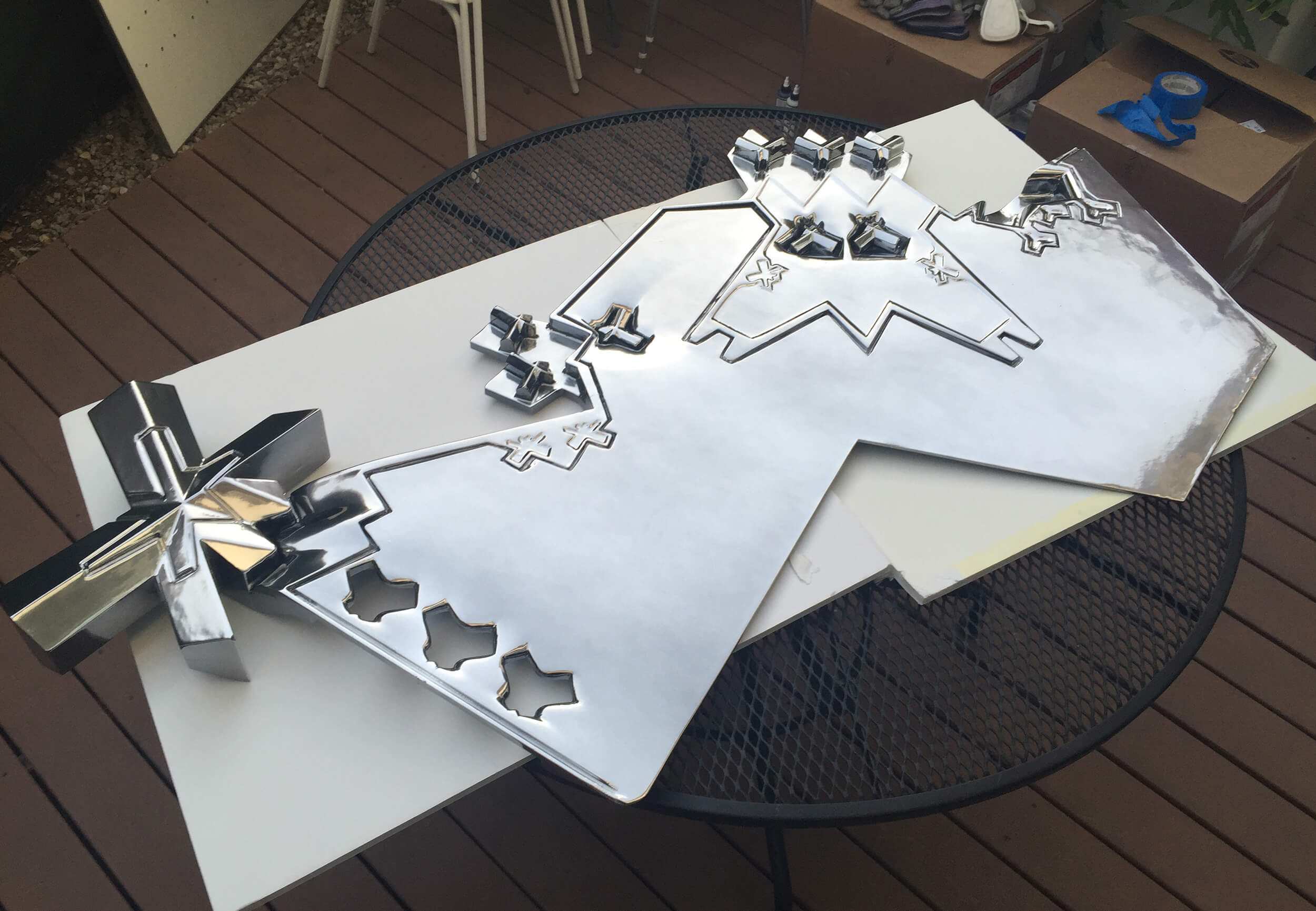

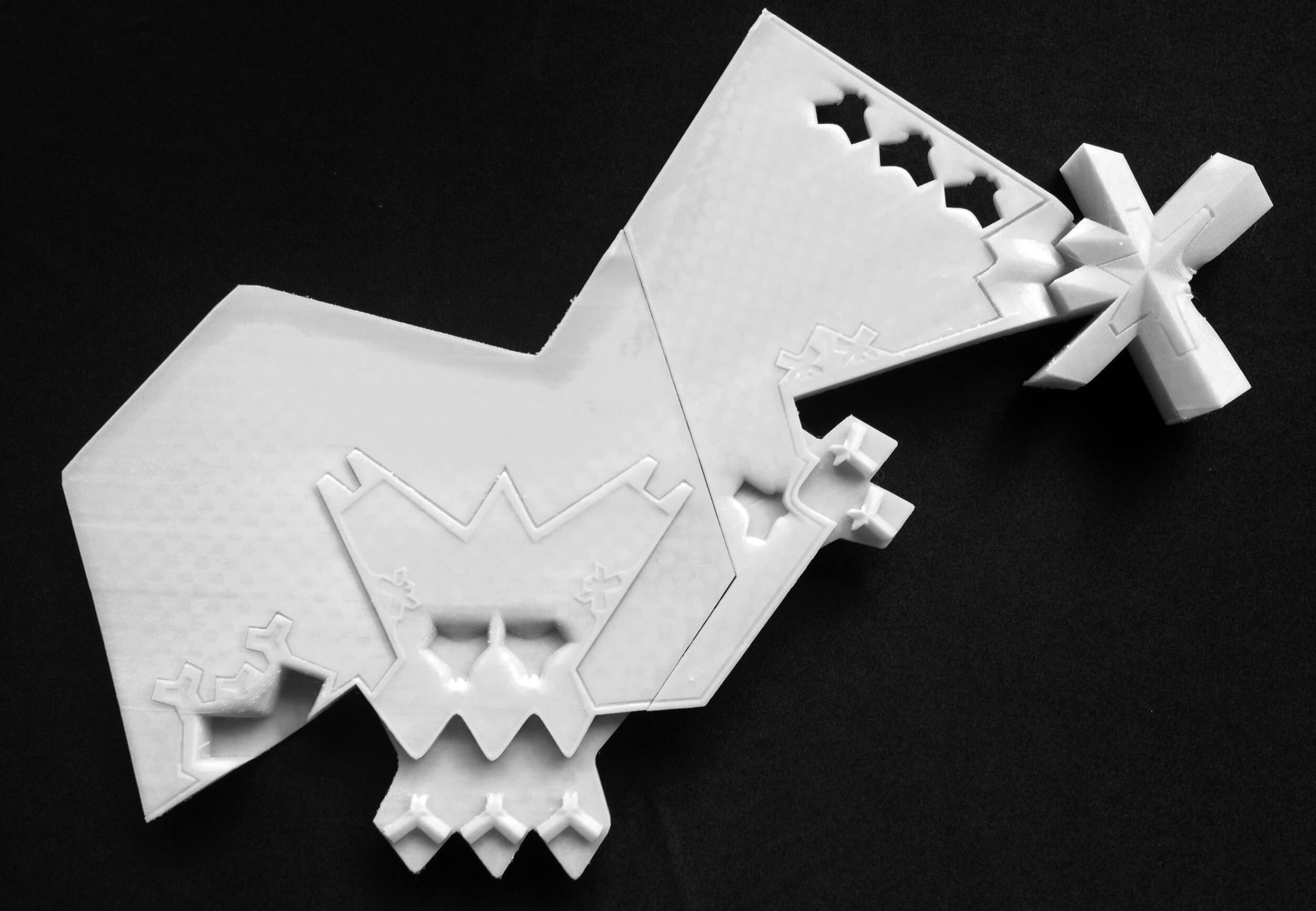

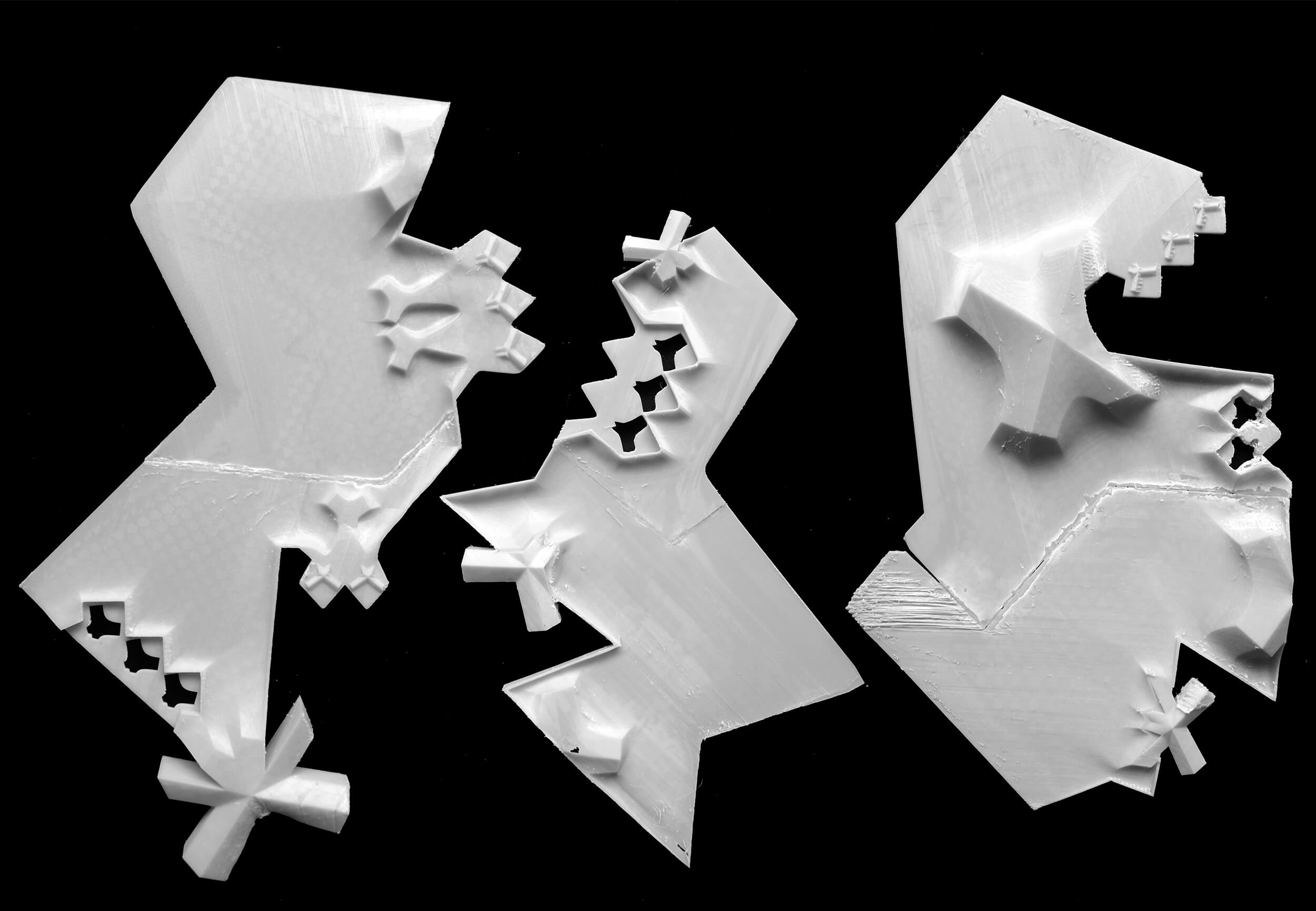

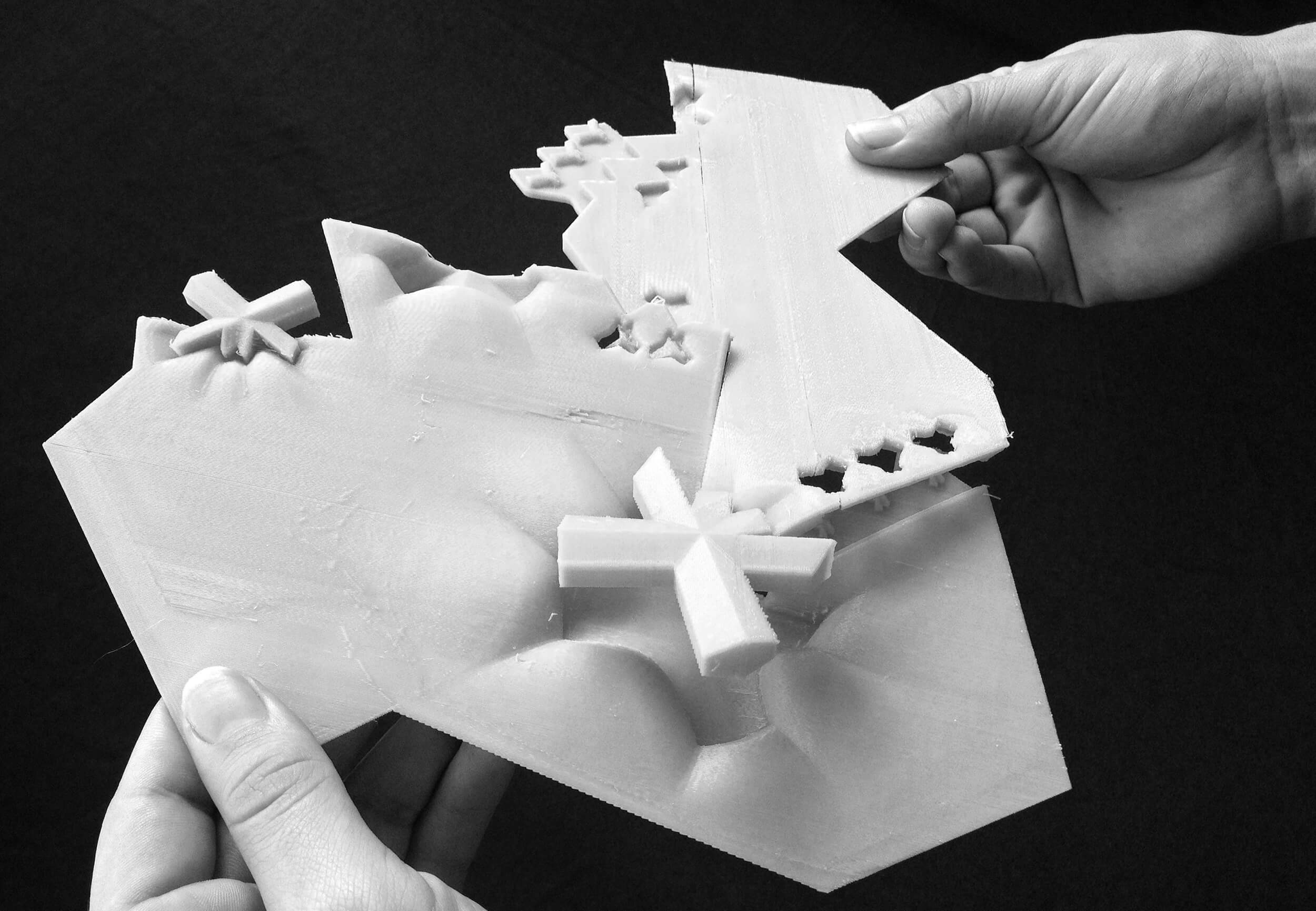

The building’s megalithic slabs lean playfully on each other, like a scale model or a house of cards. They step down the cliffs, relating to the context in a surprising, raw way.